Platinum-based green hydrogen emerging as Winter Olympics decarbonisation pillar

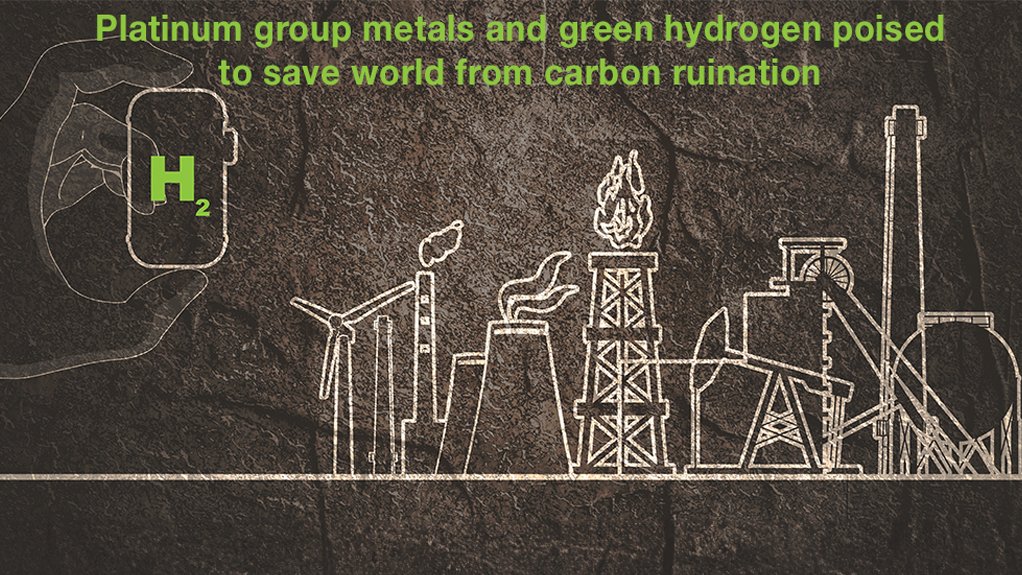

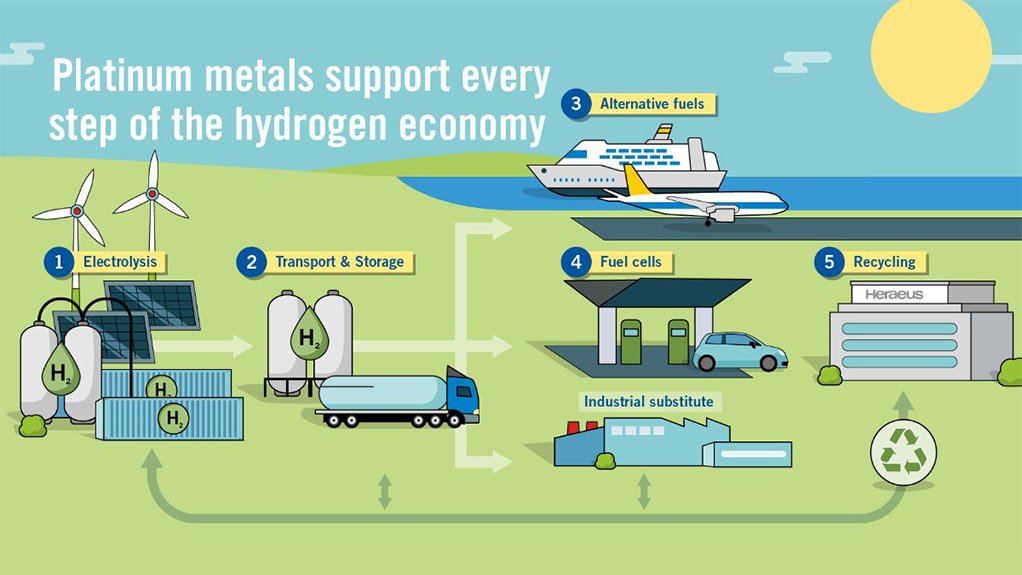

Platinum metals support every step of green hydrogen’s decarbonisation of the world.

Green hydrogen to decarbonise Ugitech stainless steel in French Alps.

Platinum group metals, green hydrogen, decarbonisation and climate abatement go together. Diagram: Heraeus

JOHANNESBURG (miningweekly.com) – Green hydrogen, which is generated with the benefit of the catalysis that platinum group metals (PGM) provide, is being increasingly highlighted as a pillar of the global decarbonisation transition that is poised to save the world from ruinous climate change.

News just out is that steps are being taken to locate a green hydrogen production facility in the region where the 2030 Winter Olympics are to be held in the French Alps.

The facility will not only provide green hydrogen to decarbonise stainless steel production at a site in Savoie, France, but it will also provide green hydrogen to decarbonise mobility in the French Alps region where the 2030 Winter Olympics are to be held.

In the process, green hydrogen will be highlighted as the sustainable model of winter tourism.

The electrolysers that produce green hydrogen most efficiently are catalysed by PGMs that South Africa hosts in abundance.

Moreover, the hydrogen fuel cells that provide decarbonised land, air and sea mobility as well as green offgrid and minigrid electricity are also PGMs dependent.

By deciding to use green hydrogen at its Ugitech plant in Ugine, in the French Alps, Swiss Steel Group evoked this comment from Lhyfe vice-CEO Philippe Desorme: “Green hydrogen can and must be deployed as quickly as possible.”

Euronext-listed Lhyfe is designing the green hydrogen production unit to have a capacity of up to 12 t a day as part of the plan to develop a local hydrogen ecosystem in the French Alps.

“The energy transition is going to become increasingly necessary to ensure the long-term survival of our industries, and green hydrogen is emerging as one of the pillars of this transition,” Desorme added in a release to Mining Weekly.

Ugitech development director Frédéric Perret highlighted in the same release that the next step is to roll out this new green hydrogen solution to all systems for which direct electrification is not a compatible option.

The project planned is expected to eliminate the emission of 16 000 t/y of carbon dioxide.

France aims to install 6.5 GW of low-carbon electrolytic hydrogen production capacity by 2030, rising to 10 GW in 2035, according to a draft update of France's national hydrogen strategy.

Meanwhile, TignesNet.com reports that the Col du Palet, near Tignes, in the French Alps, is utilising a hydrogen fuel cell to supply clean renewable electricity for hikers staying at the mountain hut, the first in Europe to benefit from hydrogen technology.

In the stationary power sector, fuel cells can convert hydrogen into electricity without producing any harmful emissions and at the Beijing Winter Olympics in China in 2022, more than 1 000 green hydrogen fuel cell electric vehicles (FCEVs) were operated to highlight the clean, green emission-free mobility that FCEVs provide.

EUROPEAN HYDROGEN BANK AUCTION

The European Union has awarded €720-million to green hydrogen projects in the first European Hydrogen Bank auction, Hydrogen Insight reported on April 30.

Three of the auction winners are located in Spain, two in Portugal, one in Finland and one in Norway.

Together they will have the capacity to produce 1.58-million tonnes of green hydrogen over ten years for use to produce green steel, green fertiliser, green chemicals as well as to supply green hydrogen derivatives to the maritime sector.

Meanwhile, the Georgia and Tennessee green hydrogen production facilities of hydrogen solutions company Plug Power of the US have achieved full nameplate capacity, the World Platinum Investment Council has reported.

Using the country’s largest proton exchange membrane (PEM) electrolyser, Plug Power’s Georgia plant now produces 15 t of liquid hydrogen a day, and its Tennessee plant contributes an additional 10 t a day. PEM electrolyser efficiency is elevated through the use of PGMs.

Before the end of this year, Plug Power expects to bring an additional 15 t a day of liquid green hydrogen production online from a joint venture plant with Olin, in Louisiana.

In a separate southern hemisphere deal, Plug Power has signed a memorandum of understanding (MOU) with Australian developer Allied Green Ammonia to supply 3 GW of PEM electrolysers from 2027 for a planned project in Australia's Northern Territory, Hydrogen Insight reported on Friday.

Green ammonia is a derivative of green hydrogen and Allied Green Ammonia is reportedly looking to produce 2 500 t of green ammonia a day.

The MOU is said by Allied Green Ammonia MD Alfred Benedict to be building on a lengthy list of leading global firms that are joining Allied Green Ammonia on its journey to establish the green ammonia production facility Down Under.

Green hydrogen and its derivatives are being seen by an increasingly growing number of governments and business leaders as holding the transformative power to reshape our planet's energy future, light the way to a decarbonised world, and firmly beat off climate change at the same time.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation